Manufacturing Process equipment for Pharmaceuticals Biotech Vaccines Foods & Beverages Cosmetics

QUALITY

Quality is the essence of any manufacturing unit. We at MEVISHI, believe in putting this core value at the forefront of our processes to ensure that the product meets all the desired standards, as per the customer and market demands. Our accreditations validate our claim for excellence in Quality.

RELIABILITY

A strong foundation of trust, transparent communication and adherence to commitments is the key to our success. We do not compromise on our core values under any circumstances and this is validated by our decade-old strong customer base. We are proud of the same and ensure a lifetime commitment to all our core values.

CUSTOMER FOCUS

Customer is our King. We believe we exist for the customers. Our products, processes and services are designed for the customers and also by the customers as we place tremendous focus on centering the entire gamut of production, innovation and creation around customer recommendations and feedback.

Who We Are

Mevish is one of the leading manufacturers of Pharmaceutical Formulation. We cover almost all the machinery required by Pharmaceutical & Cosmetics Formulation company, namely for Injectable section, Liquid Oral, Semi Solid & Tablet. We are backed by the strong foundation of our profound infrastructure. Our factory is well equipped with machine shop, fabrication shop, assembly, buffing & polishing section.

Know More

Our Products

Sterile Mixing Vessels

Mixing and blending vessels are engineered to be used in the manufacturing, storage and transfer of a wide range of liquid pharmaceutical applications. They can be used into manufactureof parenteral, expectorants, antibiotics, ophthalmic, blood plasma etc.

Read MoreMixing & Reactor Vessels

Mixing vessels are frequently used for stirring, dissolving, mixing, extraction and other processes in kilo-labs and pilot plants. Jacketed or limpet reactors permit heat exchange for better dis- solving and crystallization. Mobile mixing vessels can be transported with their content for further processing

Read More

CIP / SIPSystem

Cleaning-In-Place (CIP) & Sterilization-In-Place(SIP) are systems designed for automatic cleaning and disinfecting the system without major disassembly and assembly work. We design, develop, manufacture, supply and install Mobile and Fixed CIP & SIP Units for sanitization & sterilization.

Read MoreZero Hold Up Filter Press

Zero hold up filter press is a filtration machine used to filter liquid in pharmaceutical, chemical, beverage,and other allied industries. Working on the principle of pressure feeding and its significant properties,it is considered as the most efficient filtration machine.

Read More

Pressure Vessels

The pressure vessel is equipped with a flexible type top lid opening arrangement that can come with either a flange end or a tri clover end. This specially designed vessel is suitable for in-situ sterilization. If required, a heating/cooling jacket with insulation in SS 304 welded cladding can be provided. The end connection can vary based on the customer's specific requirements.

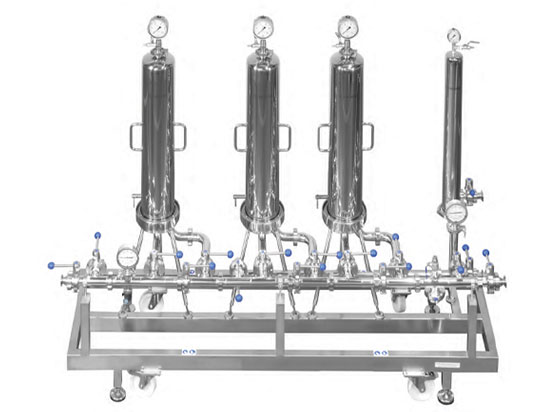

Read MoreFilteration Skids

The skid design for this equipment is compact and space-saving. There are provisions for cartridge wetting and in-situ integrity testing of filters, which ensures their proper functioning. The design is fully sanitary, with 100% cleanability and zero dead leg pockets. This allows for the efficient cleaning and maintenance of the equipment.

Read More